JSC Almaz-Antey is the monopolist producer of air defence and missile defence systems in Russia, as well as the manufacturer of Kalibr family cruise missiles. As the principal Russian exporter of weaponry, Almaz-Antey is an uncharacteristically transparent company, and the most outspoken advocate for the import of production equipment from the West. The transparency of Almaz-Antey made it a favourite object of OSINT investigations.

In this post, we will cover a single Almaz-Antey enterprise: the JSC Kalinin Machine-Building Plant. Yekaterinburg-located, it shares the same production facility with the OKB Novator, the Kalibr missiles producer. Historically, the Kalinin Plant has been a major producer/repairer of missiles for the S300, Buk and Tor air defence systems. We, however, have a strong reason to believe that with the start of the Special Operation, it focused on manufacturing Kalibr missiles instead.

KALININ MACHINE-BUILDING PLANT

The first thing to understand about a long range missile is that its production requires precise parts. Most components of tight control and convoluted geometries must be machined and cannot be reasonably produced by any other method. This makes machining a central production process at the missiles industry. Most of what a missile plant is doing is machining. Consequently, the question of how to produce a missile is mostly a question of how to machine parts.

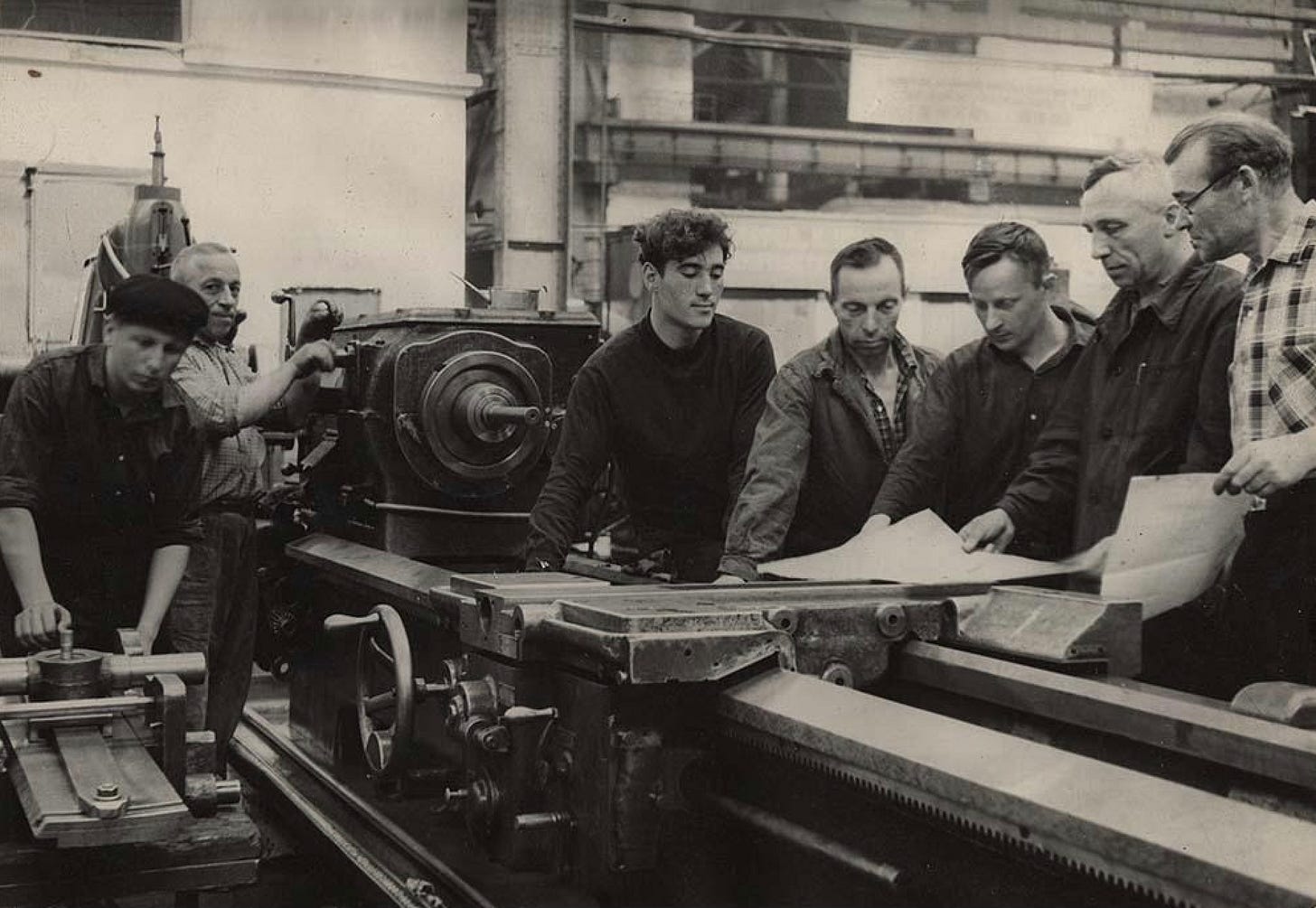

That’s how the Kalinin Plant was machining parts in the late USSR.

Kalinin Plant, Workshop 17. Conventional vertical mills, operated manually. 1976

In the late Soviet era, it was mostly equipped with the manually operated conventional machines. A conventional operator had to read the blueprints, interpret them, and design the machining strategy based on his interpretation. After that, he would direct the machine manually, getting the feedback from it with his eyes, hands, and ears. Quality and consistency of the final product heavily depended upon the operator’s personal skills and expertise. It was a personal interpretation of a drawing by an operator that the production process was based upon.

Kalinin Plant, Workshop 1. Late 1970s

The operator expertise could not be bought, nor forced under a gunpoint. Including a significant element of the tacit knowledge, it was passed from a master to an apprentice in a process of the years-long one-on-one mentorship. Considering the length, and the difficulty of training, it took a decades-long nation scale effort for the USSR to foster the workforce capable of mass producing the sophisticated weaponry manually. With the collapse of the USSR, the tacit knowledge accumulated over the generations of Soviet war production was lost. It was not and could not revived afterwards.

Starting from 2003, Putin brought the Russian military industry back from the dead with the mass import of CNC machining equipment from the U.S. allies. Transition from the manual to computer control allowed to compensate for the loss of Soviet expertise and reboot the production of complex weaponry that new Russia could not manufacture otherwise. Allowing to mass produce precise parts with a minimal input of qualified labor, CNC cutting machines become a universal instrument of the Russian war production

Let’s have a look at the visuals of how the Kalinin Plant is producing missiles now:

Keep reading with a 7-day free trial

Subscribe to kamilkazani to keep reading this post and get 7 days of free access to the full post archives.