Soviet Union was making a lot of weaponry.

No, it was making A LOT of it.

Soviet output of armaments was absolutely gargantuan, massive, unbeatable. “Extraordinary by any standard”1 , it was impossible for any other country to compete with. Soviet superiority in quantity lasted until the very last days of the USSR. From 1975 to 1988, the Soviets produced four times as many ICBMs and SLBMs, twice as many nuclear submarines, five times as many bombers, six times as many SAMs, three times as many tanks and six times as many artillery pieces as Americans2.

“In every category, Soviet production has exceeded that of the United States”

Which raises a question:

How on earth could the USSR produce so much?

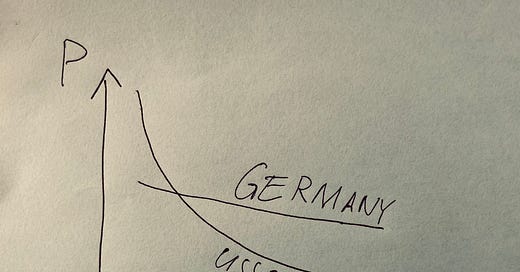

It is not only that the USSR invested every dime into the military production. It is also that the Soviet military industry was designed for the very large volumes of output, and worked the best under these very large volumes. The “USSR spent more” explanation suggests linearity (n times more investments, n times more weaponry), while the actual economy of military production were non-linear.

I will demonstrate the logic of Soviet Mode of Production and the non-linearity of war economy on a relatively simple, straightforward example.

In the WWII, both the Soviets and Germans had to build massive quantity of tanks in a relatively short time. Strange it may sound, both the Soviet and Germans approached this seemingly identical task differently. Germany produced rolled turrets, and the USSR - casted ones. This difference is methodology reflects a deep, fundamental difference in the philosophy of war production4.

German approach

You take rolled armour plates

Why rolled plates? Two reasons.

First, because the rolled steel is better5.

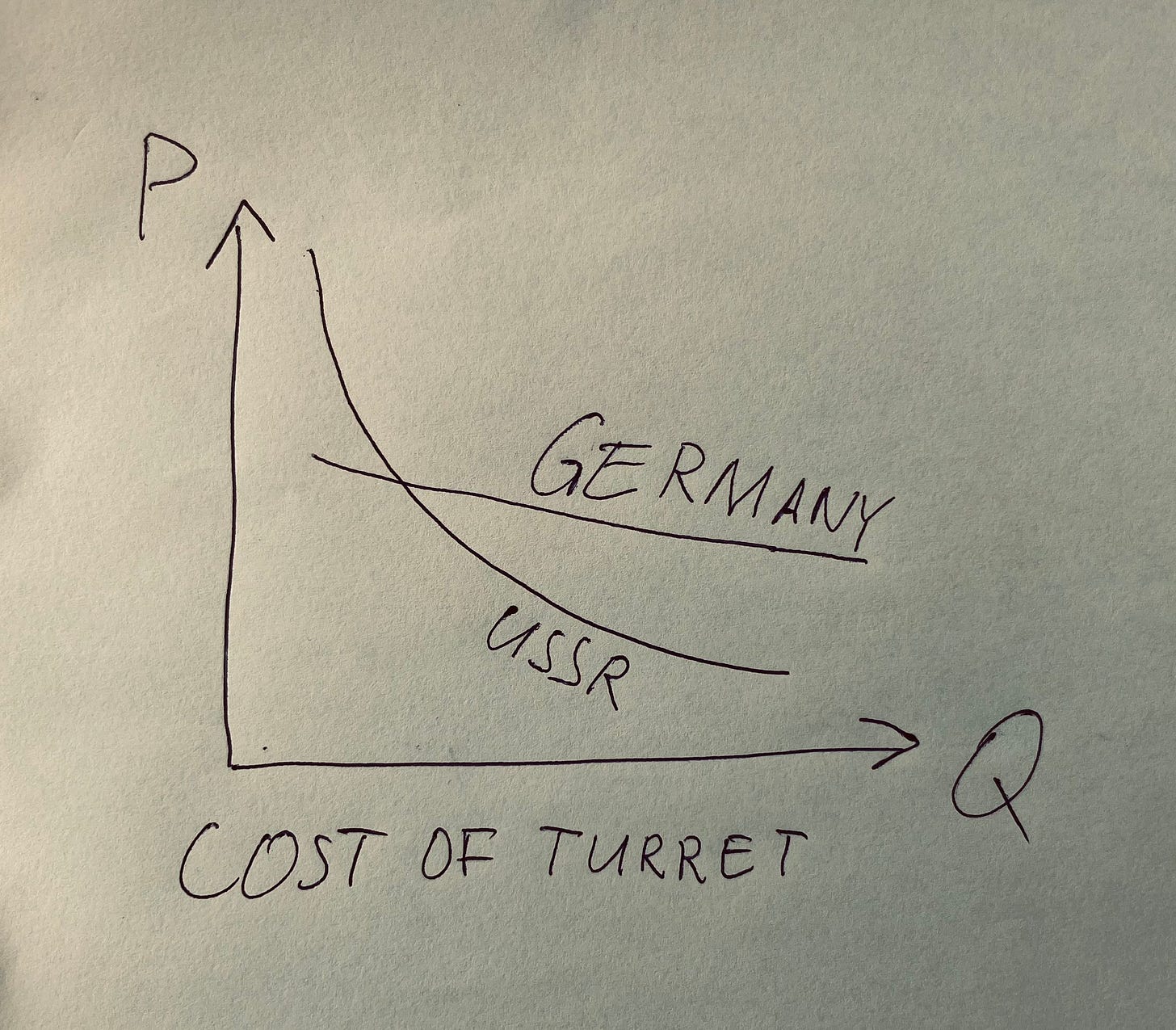

When you roll a steel plate, you don’t just change its form. You change its internal structure and, therefore, mechanical properties of material.

Before rolling, a plate has chaotic, heterogenous internal structure. It is basically the liquid that crystallised and crystallised chaotically. The grains of metal vary in size, in shape, they are directed differently. Material structure is pretty much random. When you compress it with rolls, you reorganise the material. Grains become uniform in size, in shape, in direction.

Material becomes stronger, very much stronger.

Second rationale is less obvious, yet equally important.

The thing with rolling is that you can outsource it to the civilian metallurgical plants. This methodology, therefore, allows for the open architecture of military production. You do not have to build a hyper mega super pro gigantic military plant. It is perfectly fine to maintain a military industry of limited size and, should the necessity arise, outsource production operations to civilians. For that to happen, however, you need to be building weaponry with operations that are outsourceable.

Like rolling.

Now as you procured rolled armour (on the civilian metallurgical plants), you need to bend it into shape, and weld it6. That part you do on a military enterprise. Of these two operations it is the welding that makes for the bottleneck in turret production.

Why? Because it was a manual operation requiring highly qualified craftsman labor. To weld armoured7 steel you needed trained, experienced welders. Consequently, your capacity to produce turrets this way was hard constrained by the quantity of these craftsmen. The thing with welder expertise is that it was not fully codified, including a very significant element of tacit knowledge. Training an expert welder welder was long, expensive, and necessarily included learning from a personal example of his seniors.

How many expert welders did the Germany have?

More than anyone.

The thing with Germany is that it had the greatest and the largest reservoir of expert craftsman labor in the world. Even today, the uninterrupted tradition of craftsmanship gives Germany8 a major upper hand, allowing for high complexity of products and designs. In the pre-CNC world9 this advantage used to be far, far greater.

For Germany, the bottleneck of experienced labor was wider than for anyone else in the world. Still, it was a bottleneck.

German Panther Tank. You can clearly see the shapes of individual metal plates.

Now let’s do the Soviet Union.

Keep reading with a 7-day free trial

Subscribe to kamilkazani to keep reading this post and get 7 days of free access to the full post archives.